Welcome to IEPCC Solutions

Your challenges in service support ends with us

IEPCC Solutions is a One stop Integrated solutions provider for EPCC Projects. We offer complete turnkey solutions for petroleum, oil & Gas, Offshore-Onshore and marine industries.

Our years of experience in the industry, Realizes the dire need to mitigate the challenges within the industry with an end to end support and help you focus on your core business and that gives us an opportunity to be an extended arm in partnering the success for a common interest.

The cost & resources optimization, continues productivity improvement, innovation in industrial technology and “total ownership culture” are essential in business in order to lead & be the best in class. EPCC ensures to reflect and participate hand in hand with our valued customers.

Knowing best the Customer sensitivity and maintaining long-term retention of clients are our main objective. In order to achieve such efficiency we draw expertise from well proven and seasoned professional, process & systems in the field and fulfil the gaps.

Continuous improvement and the best efficiency are achieved by fool proof quality & HSE systems which are monitored and maintained. The Conscious quality and safety culture is nurtured even within our partners and 3rd party service providers through a systematic learning and monitoring process.

Our Vision

To enable petroleum and marine industry to achieve professional excellence and sustain positive growth.

Our Mission

To be an active contributor to support petroleum and marine industry to sustain core business growth through end to end service support , with best in class quality and safety, effective cost position , innovative methods and challenging time line.

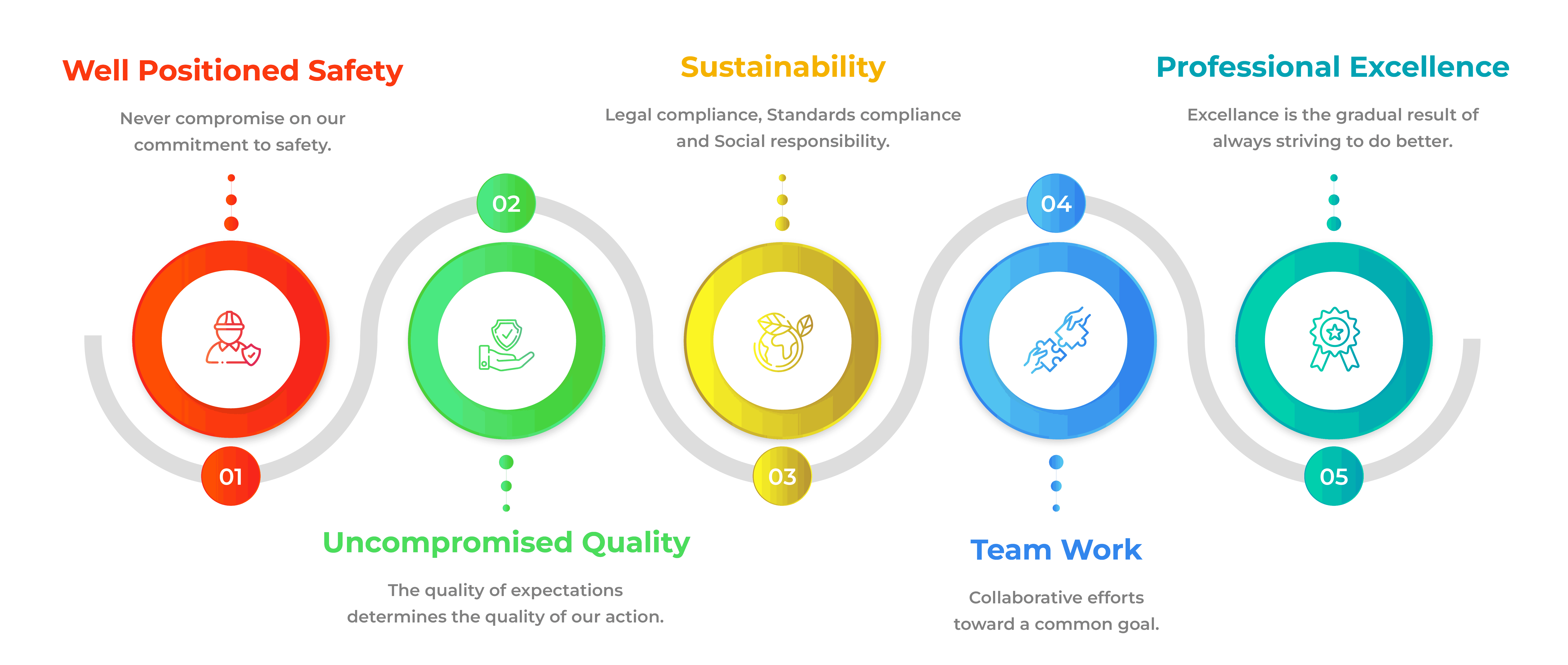

Our Core Values

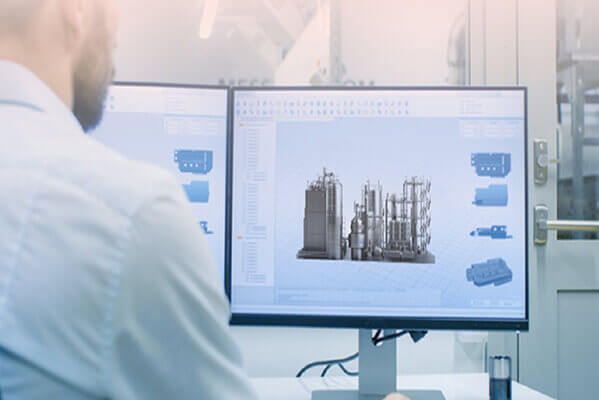

What We Do

We provide an integrated solution at every stage of your projects and ensure successful results of our clients. We clearly understand the client’s goal, strategy, project requirements and Scope. As a result, we are able to deliver our services more efficiently, on-time and on-budget.

Benefits of Working with Us

IEPCC Solutions mission is to support our clients looking for more efficient solutions to complete their projects. We adopt the best methodology for delivering projects on-time and on-budget with highest quality and Safety standards. We ensure success by providing integrated solutions and extensive expertise and resources throughout the project phase.

Hence, we from IEPCC would like to be an extended arm within your company for a common interests with mutual respect and deliver the goal.

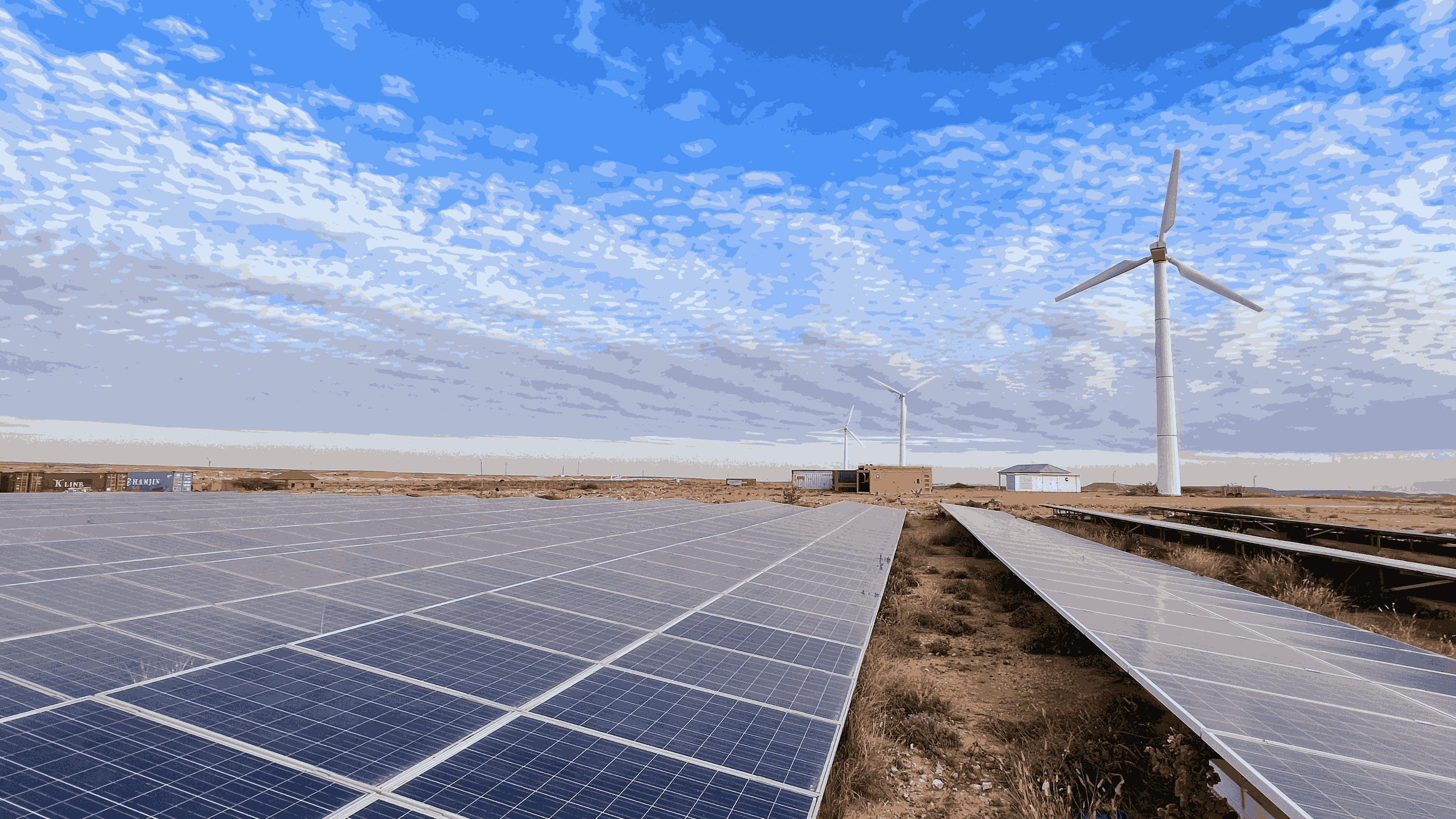

Our Projects

We provide an integrated solution at every stage of your projects and ensure successful results of our clients. We clearly understand the client’s goal, strategy, project requirements and Scope. As a result, we are able to deliver our services more efficiently, on-time and on-budget.

contact us

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)